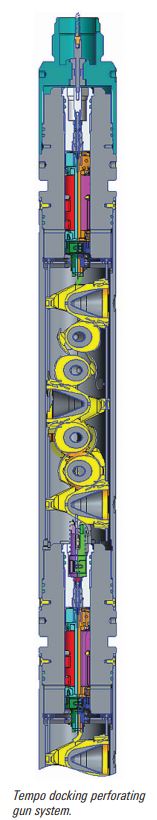

Schlumberger’s (ticker: SLB) wireline group has come out with a new technology system that it says will allow operators to more cleanly perforate a well. The company’s new ‘Tempo’ is an instrumented docking system that delivers real-time measurements in perforating operations. Tempo combines a new plug-in gun design with real-time advanced downhole measurements that measure the well’s dynamic underbalance.

New plug-in gun

The new plug-in gun design “significantly simplifies assembly, arming and firing,” according to Schlumberger. The new gun can be armed offline in significantly less time than conventional systems, increasing safety, Schlumberger’s spec sheet for Tempo reports.

Perf multiple zones with max explosives in a single trip

The docking components allow deployment of up to 40 guns for selective initiation to perforate multiple reservoir zones with a maximized explosives payload in a single trip in the well.

Tempo eliminates the variability introduced by wellsite crimping and wiring, which are the primary causes of misruns and misfires, according to a statement by Schlumberger.

Schlumberger said its system design was extensively tested by an independent third-party organization to qualify as an API RP 67 Group 2 initiator for use without having to establish radio frequency (RF) silence at the wellsite. Operational risk is also mitigated by the ability to confirm system integrity both at surface and downhole, prior to positioning at the target interval, the company said.

Test results

The Tempo system is being deployed worldwide following field trials in Egypt, Oman, Kuwait, Algeria and Ecuador. In Egypt, the Tempo system’s onboard diagnostics and RF filtering technology provided operational assurance and RF protection during 11 perforation runs with no impact on simultaneous operations.

Technical details

Technical details on the Tempo system are here. Download a Tempo spec sheet here.