“Our analysis helps our customers find what levers drive production.”—Leen Weijers, VP of Engineering for Liberty Oilfield Services

After The Oil & Gas Conference® wrapped up in Denver last week, EnerCom hosted the debut of Oilfield Tech & Innovation Day, where the latest technologies for the E&P industry were the focus.

The day was designed for both VCs and majors who invest in extraction technologies and for companies who have commercialized technologies that are already improving recoveries and are available for operators now. This story is Part 4 of a recap of Oil & Gas 360®’s coverage of Oilfield Tech & Innovation Day.

Liberty Oilfield Services

Liberty Oilfield Services is a Denver-based oilfield service company focused on stimulation services to optimize well production. It offers hydraulic fracturing design and execution services. It uses real data to optimize field development and increase production. Liberty Oilfield Services is currently working in the Permian, DJ, Williston, and Powder River basins.

Liberty Oilfield Services has developed multiple technologies such as PropX®—to reduce dust, noise, and truck traffic; Quiet Fleet® to reduce noise from fracture activities; and the Spirit Fluid System® to place more proppant with less gel.

Liberty’s presentation during EnerCom’s Oilfield Tech & Innovation Day gave information on multi-variate analysis for completion optimization and minimizing the cost per barrel of oil equivalent. The company’s examples were based in the Williston area in North Dakota where it is currently working with a new slick water design, larger volumes, and larger pump rates. Liberty’s services ultimately focus on increasing its clients’ EUR and reducing the clients’ costs.

In its services, Liberty offers completion optimization tools, some of which involve big data visualization, big data statistics, and calibrated fracture and reservoir modeling.

The company’s analytical focus utilizes petro-physics, completion, and production data sourced from both public and private data sources. The company ultimately incorporates this data into multivariate analysis. The multivariate analysis tool is called Liberty Frac Trends, and can be used to predict production as a function of stage spacing, proppant concentration, average proppant loads, and treatment rates.

The predictive technology was designed with the intent of allowing Liberty’s clients to optimally design completions and evaluate how changes to any completions parameter might impact the ultimate recovery from that well.

View the Liberty presentation webcast here.

Belgrave Oil & Gas Corp.

Belgrave Oil & Gas Corp. is a private petroleum development company. The company’s primary focus is on the development and application of high impact improved/enhanced oil recovery (IOR/EOR) technology to increase oil and gas production, improve recovery, and prove additional reserves. The company has operated in Canada, China, Colombia, India, Russia, and Trinidad.

The company believes that conventional primary and secondary recovery methods will only produce about one-third of the oil discovered and that potentially tens of billions of barrels of additional oil remain to be recovered in North America alone.

During its presentation, Belgrave Oil and Gas spoke about the potential for air injection EOR, which is often also called fire-flooding or in-situ combustion. The premise of air injection is that air is injected into mature conventional reservoirs to push residual oil towards a producing well. When air is injected into deep, conventional reservoirs hydrocarbons in place are often ignited and heated. The heavier components of the hydrocarbons burn, heating residual oil and allowing it to be pushed out of pore spaces.

When coupled with water injection, the combusting oil is pushed both by air, steam and water, and further mobilized towards a producing wellbore. The company believes that utilizing air injection in mature conventional reservoirs will allow companies to reactivate reservoirs that were previously considered uneconomic.

Belgrave said that experiments and field applications for air injection have been successful, and that the technology may have broader applications in other reservoirs. The company compared the new technology to other EOR methods, such as CO2 or surfactant injection, and noted how air injection is less capital intensive and much easier to control.

View the Belgrave presentation webcast here.

Comitt Well Solutions

Commit Well Solutions is a downhole tool company that builds technologies oriented towards revitalizing wells. The company said that its primary goals are to maximizing the EUR of existing wellbores, optimize the deployment of operators’ resources, and reduce the use of personnel.

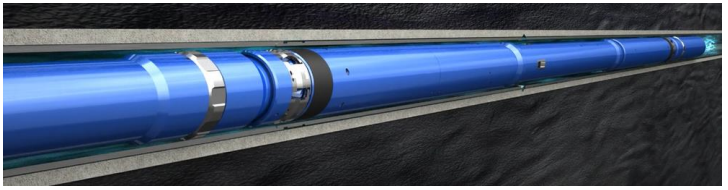

During its presentation at EnerCom’s Oilfield Tech & Innovation Day, Comitt spoke about pin-point placement of hydraulic fractures and perforations using its downhole tool, the Excite System.

In re-fracturing mature wells, the Excite System is meant to create new fractures and apply new completions designs to old wells. The Excite system targets legacy assets that have lost production gradually. By re-fracturing those assets and applying new, better understood completions methods such as increased stages and higher proppant concentrations, Comitt hopes to introduce new production to old wells.

View the Comitt presentation webcast here.

GroundMetrics

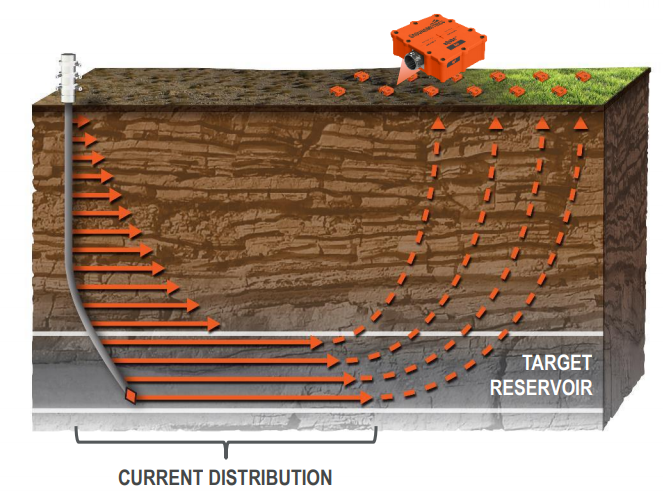

GroundMetrics is an oilfield service-company that has designed products and services allowing operators to better characterize their reservoirs. The company provides surveys using its electric field sensors to build an oil saturation profile on a field-wide scale.

During its presentation, GroundMetrics spoke about how its sensors and survey technologies can benefit operators and how its technology differs from historic oilfield practices.

By utilizing an operator’s cased wellbore as a conductor, the company can create an electric field within the reservoir. The manner in which that electric field interacts with the fluids in the reservoir, once detected by the company’s electronic field sensor, can grant an operator an insight into where the most significant amounts of oil remain.

Instead of finding resistivity and saturation profiles along the wellbore alone, GroundMetrics has the ability to do so on a scale that can provide an operator with a better understanding of uncontacted, unproduced zones, flow barriers, and general fluid saturation within the field as a whole.

This insight into the reservoir saturation profile can help operators with reservoir characterization, offshore characterization, and hydraulic fracturing. The company’s technology can also be utilized for casing diagnostics.