Unconventional EOR a major new frontier for the industry with a possible 50%+ recovery improvement

The fourth day of EnerCom’s Oil & Gas Conference® saw the debut of the Oilfield Tech and Innovation Day, when companies with innovative ideas for oil and gas operations presented their technology. Core Laboratories (ticker: CLB) Reservoir Description VP Larry Bruno outlined the company’s current operations and focus.

Unconventional EOR can improve recovery by more than 50%

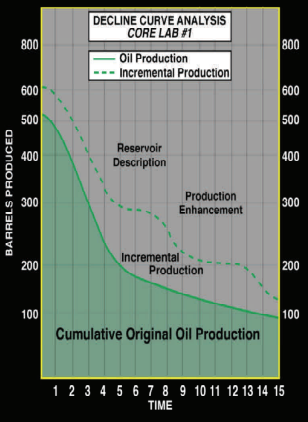

Core has two primary business segments, reservoir description, which focuses on laboratory-based testing and rock and fluid analysis, and production enhancement, which includes field applications, completion diagnostics and perforating systems.

In both Core’s TOGC presentation and its Tech Day presentation, the company emphasized the importance of the decline curve, and what can be done about it. Wells naturally decline in production as time goes on, as standard operation depletes the reservoir. This is unavoidable, even a gold-plated Cadillac of a frac job will not keep a well from declining in production.

In conventional reservoirs, the response is enhanced oil recovery (EOR). This allows a well to increase its production beyond standard levels, producing perhaps over 40% of the total amount of oil present. Unconventional wells are more difficult, and trying to use standard EOR methods does not produce results.

However, Core believes it has identified a process for improving unconventional recovery factors beyond the standard ~9%. According to Core, it has achieved 15% recovery factors in laboratory tests. While this may not be a tremendously high number, it represents an increase in ultimate recovery by more than 50%, which can have a profound effect on economics.

Core’s technique involves using its analysis expertise to develop a blend of gasses that will allow the oil trapped in the formation to flow, improving recovery. The standard process involves injecting the gas into a well, allowing the gas to mix with the oil and make it more mobile. Then the well can be brought back on to production, producing the injected gas and the newly-mobile oil.

Chemical tracers can quantify stage effectiveness

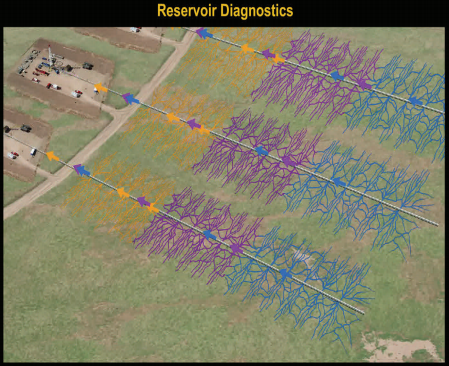

Another program presented by Core is its reservoir diagnostics system. This involves the company putting different tracer chemicals at each fracture stage in a well, then allowing the well to produce and analyzing the well’s production. Core’s use of different chemicals at each stage mean that it can evaluate the quality of each individual stage.

If, for example, the well is producing a great deal of tracer associated with stage one, and virtually no tracer from stage two, Core can quantify the production contribution of each stage. This allows companies to identify the effectiveness of each individual stage, instead of just examining the total production of the well.