“As drilling gets more efficient, more capital is being allocated to completions” – Cold Bore Technology’s Tyler Sanden

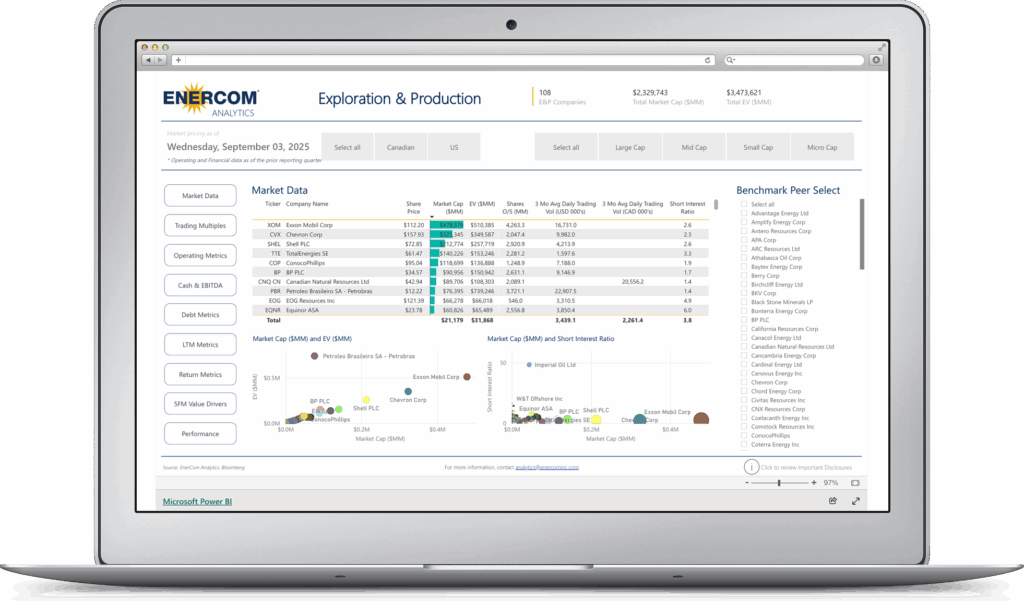

Last week, following The Oil & Gas Conference® in Denver, EnerCom hosted the debut of Oilfield Tech & Innovation Day, at which technology developers with solutions tailored primarily for the E&P industry presented their strategies and technologies. This story is Part 2 of a recap of Oil & Gas 360®’s presenter innovation coverage.

Cold Bore Technology

Cold Bore Technology presented its technology at the debut of EnerCom’s Oilfield Tech & Innovation Day at the Denver Downtown Westin hotel on Aug. 17, 2017.

Cold Bore Technology has built its business in the realm of wellbore and subsurface monitoring using acoustic wave technology. The monitoring service allows operators to better understand the performance of different operations in the wellbore environment.

When an operator is undergoing a sliding sleeve completion, it will drop a metal ball down into the sliding sleeve device to activate the sleeves and allow fracturing to begin. Cold Bore’s technology allows the operator to “hear” when the ball makes contact with the sleeve, and to detect if the sleeve opens—which allows the company to avoid beginning fracturing activities on a wellbore that is not yet ready for completions. Cold Bore’s technology allows operators to save money by avoiding ineffective completions.

In addition to the benefit of its acoustic monitoring service, Cold Bore spoke about its Smart Pad® technology, which allows real-time monitoring of surface infrastructure.

Cold Bore Technology’s EnerCom Oilfield Tech & Innovation Day webcast is available here.

Heal Systems

Heal systems presented its technology at the debut of EnerCom’s Oilfield Tech & Innovation Day at the Denver Downtown Westin hotel on Aug. 17, 2017. The company’s innovation is specifically in the realm of artificial lift.

During its presentation, HEAL Systems spoke about its production technology specialized for artificial lift designed for both horizontal and lateral wells.

Its HEAL artificial lift enhancement system is built to be placed in the curved portion of a horizontal or lateral well—i.e., the heel of the well—where it can be paired with ESP pumps, plunger pumps, or other types of artificial lift. One of the major drawbacks of horizontal wells is the accumulation of fluid in the horizontal section, where gas will build up and escape in “slugs.” The HEAL system corrects, or “heals”, this condition by destabilizing the gas built up in the horizontal section, and regulates production by eliminating the slugs.

By regulating production out of the horizontal section, HEAL Systems’ technology improves the overall recovery out of the well, maximizes recovery efficiency, and maintains the health of the near-wellbore area during production.

Heal Systems’ EnerCom Oilfield Tech & Innovation Day webcast is here.

Gradiant Energy Services

Gradiant Energy Services presented its technology at the debut of EnerCom’s Oilfield Tech & Innovation Day at the Denver Downtown Westin hotel last week. The company’s water-centric business has allowed it to build a niche in disinfection, treatment and reuse of produced water.

Gradiant Energy Services provides oil and gas operators with safe and economically competitive reuse and recycling of produced and flowback water. Gradiant’s services are tailored to its clients’ specific wells.

During its presentation, Gradiant Energy Services spoke about the services it provides, which include:

- Bacteria Treatment

- Re-usable clean brine

- Evaporative disposal

- Desalination

An industry-wide increase in demand for fracturing services has induced a need for water treatment technologies and services. Gradiant believes that the demand for the treatment and reuse of produced water from fracturing activities will expand as water becomes increasingly scarce and vital in oilfield operations, and as the regulatory environment surrounding water shifts. Gradiant Energy Services has a presence in multiple basins the U.S.

Gradiant’s Oilfield Tech & Innovation Day presentation webcast is here.

Transworld Technologies

Transworld Technologies presented its technology at EnerCom’s Oilfield Tech & Innovation Day at the Denver Downtown Westin hotel on Aug. 17, 2017.

Transworld Technologies is based in Golden, Colorado, and offers BioEnhanced Petroleum Recovery solutions. Its products are designed to increase recovery factor, accelerate production and extend economic life of mature oil and gas fields by stimulating the existing microbial colonies to act as diverters.

Transworld’s technology works in conventional and unconventional reservoirs and does not required any changes to ongoing waterfloods or new pumping infrastructure. The two production solutions offered by Transworld are: Activ8®, which works in waterflood and water drive fields by activating microbes in the reservoir to generate methane gas and Reactiv8®, which works in biogenic gas fields. Both products extend the productive life of the reservoir.

Understanding the biology of the oil and water and the microbes that are already existing within the reservoir allows Transworld to generate activators or stimulants to increase the sweep area of the waterflood. This technology can only be used in mature wells that have gone through and are able to continue waterflooding.

Activ8® and Reactiv8® increase oil recovery by ensuring the waterflood contacts more of the reservoir matrix, which will increase the overall sweep efficiency and can create an increase in production of between 25-50%. It takes between three and 12 months to reach a plateau in production. Transworld noted that equipment payout typically occurs between 12 and 18 months and that its technologies create a return on investment between three and seven times the cost of the product.

Transworld said that it must record both the production and injection data, and have samples from the producing field to effectively determine the results of utilizing its technology.

In its presentation, the company also said that its technology requires very little in the way of specialized field equipment—needing only a tank and pumping unit—and that the field footprint of instituting its recovery method fits on a single skid. Transworld noted that, once underway, the well production can be improved for between four and six years, and that the technology can be re-applied after that time in a field in which it has already been used.

Transworld’s Tech Day presentation webcast is available here.