Blackbird Energy Inc. (ticker: BBI) completed the construction of its 100% owned and operated 12-14-70-7W6 Elmworth facility and gathering system near the budget of $16.1 million. Commencement of production is anticipated by the end of January 2017, Blackbird said in a press release today.

In conjunction with the construction of the facility and gathering system, Blackbird has tied-in the 6-26, 5-26, 2-20, and 02/2-20 wells. The 3-28 well is scheduled to be tied-in by calendar Q2 2017. The 2-20/11-9 well will be tied-in as part of Blackbird’s eastern infrastructure development plan, which is currently in the front end engineering design phase.

Blackbird’s facility will have an initial capacity of approximately 10 MMcf/d of natural gas plus associated liquids of approximately 1,500 bbls/d, for aggregate throughput of approximately 3,150 boe/d. The facility includes liquids recovery and stabilization. The facility has been designed to allow for future production expansion beyond 10 MMcf/d, 1,500 bbls/d and 3,150 boe/d.

While 3,150 boe/d represents the facility’s current capacity, Blackbird’s current sour natural gas processing contract amounts to 6.3 MMcf/d plus associated liquids and Blackbird’s current Alliance sales gas takeaway agreement amounts to 5.0 MMcf/d of natural gas to be shipped to the Chicago market. Blackbird is currently evaluating numerous alternatives to increase both its sour processing and sales gas takeaway capacity in the Alliance pipeline system and/or the TransCanada NGTL pipeline system.

Blackbird expects to achieve its Initial Production Capacity within approximately four weeks of commissioning its Facility and Gathering System, as the Initial Wells are still cleaning up and recovering load fluid.

Drilling Update

Blackbird has completed the previously announced 3-28 well drilling operations and will commence completion operations in the near term. Following the 3-28 drilling operations, the rig was released and spud the 2-20/11-9 well on December 28, 2016.

Blackbird also announced that its completions technology investment, Stage Completions, has deployed its Bowhead II System across a number of basins, with six Stage Systems deployed to date and an additional 12 Stage Systems estimated to be deployed by the end of Q1 2017.

Milestone

Blackbird’s Chairman, Chief Executive Officer and President Garth Braun said, “The completion of our infrastructure construction marks an important milestone in the transition of Blackbird to a producing oil and gas company. Looking forward, we are focused on increasing our sour gas processing throughput, reducing costs, and prudently developing our Elmworth/Pipestone asset in a responsible manner. With this significant infrastructure capital behind us, the groundwork has been laid for scalable growth using cash flow and pad-drilling techniques, which should further decrease our all-in well costs.”

Montney Update

The previously announced 3-28 Upper Montney well was spud on November 23, 2016 from surface location 11-15-70-7W6 and drilled to a measured depth of 4,120 meters, including an approximately 1,500 meter lateral section to 15-21-70-7W6. This well was drilled in an area that has been deemed the “Volatile Oil” window by an industry leader. On a preliminary basis, estimates indicate that the 3-28 well was drilled approximately $0.3 million under the budget of $3.0 million.

Completion operations on the 3-28 well commenced on January 10, 2017 utilizing the Stage System. The completion program will place approximately 50 tonnes of sand per stage over approximately 56 stages, the highest frac intensity of any Blackbird wells to date. Consistent with practices of a regional industry leader, Blackbird plans to let the frac fluid imbibe in the 3-28 well for approximately four months before flowing the well back into the Gathering System, with initial production anticipated by June, 2017. This is anticipated to reduce testing and flow-back costs.

On December 28, 2016 Blackbird spud its sixth Montney well, the previously announced 2-20/11-9. This well targets the Middle Montney at Elmworth/Pipestone in the “Volatile Oil” window. The well was spud from surface location 11-9-70-6W6 and will have a lateral length of approximately 1,950 meters to a downhole location of 2-20-70-6W6.

Subsequent to the 2-20/11-9 drilling operations, Blackbird will conduct a large-scale, high-tonnage slickwater completion program similar to the 3-28 program, again utilizing the Stage System. The completion program will place approximately 50 tonnes of sand per stage over approximately 80 stages.

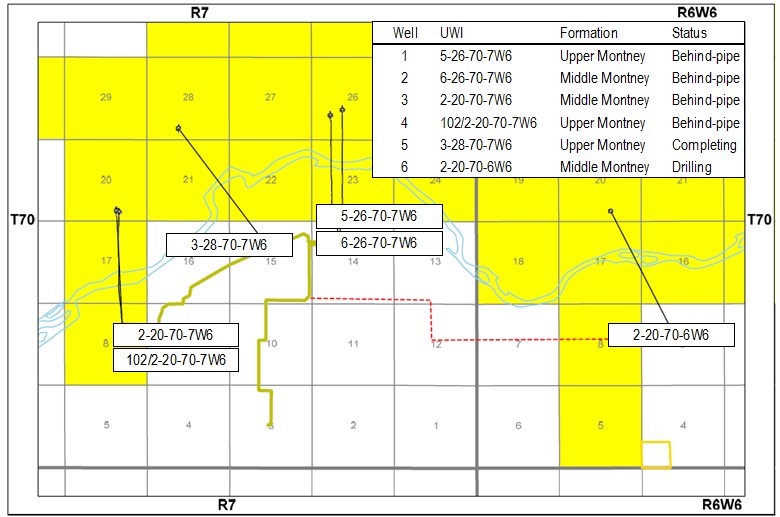

Resource Delineation and Land Retention

Upon completion of Blackbird’s accelerated business plan, the company will have a total of three Upper Montney wells and three Middle Montney wells either producing or behind pipe. These wells will span over two townships, with the 02/2-20 and 2-20/11-9 wells being approximately six sections apart on an east/west basis. This drilling program has delineated a large portion of Blackbird’s contiguous land block. See Figure 1 for an illustration of these well locations and Blackbird’s expected future eastern gathering system.

Retaining Elmworth/Pipestone Lands

A second business objective of Blackbird’s accelerated business plan was to strategically retain core Elmworth/Pipestone lands. Upon successful completion of the 3-28 and 2-20/11-9 drilling programs, 14 core sections of Elmworth/Pipestone land that was set to expire is expected to be retained, leaving only four non-core sections of land with expiry dates within fiscal 2017. The Company expects to manage any potential expiries going forward through the execution of its business plan.

“Through our accelerated business plan, we expect that we will retain all core Elmworth/Pipestone lands that would have expired during fiscal 2017,” Braun said.

“Our strategic delineation of the Upper and Middle Montney intervals over a large geographic area has provided us with very valuable information regarding our resource in-place, and solidifies our confidence in the next phase of Blackbird’s growth. We will continue our delineation program and proceed into a development phase on our western development block. Through this development phase, we will look to increase production and reserves while maximizing the value of our infrastructure investment.”

Stage Completions System in use in the Montney, Permian, Eagle Ford and Cardium

The roll out of the Stage System has been occurring at a rapid pace, with the technology now having been successfully deployed in six wells to date in the Montney, Permian, Eagle Ford and Cardium formations.

By the end of Q1 2017, the Stage System is expected to be deployed in an additional 12 wells by numerous senior operators in North America and Asia targeting the Duvernay, Montney, Eagle Ford, Scoop and a formation in China. Stage plans to release more detailed 2017 guidance in the next 30-60 days.