Rapid technology advances are allowing explorers and producers in Alaska to add hundreds of millions of barrels of new resources to portfolios at a cost competitive with finding oil in the Lower 48 states.

Chief among the technologies being used are advanced 3-D seismic and new data processing techniques, to define and map oil deposits in geological formations that have long been known, but were thought to be unproductive.

Companies are also using advances in horizontal drilling techniques to reach deposits.

In the last two years, over 1.5 billion barrels of recoverable oil has been found mainly in the west central North Slope and northeast National Petroleum Reserve-Alaska, areas companies have explored for years.

New exploration and delineation drilling planned this winter is expected to add to newly discovered resources.

ConocoPhillips has been the most aggressive of the new explorers but independents like Denver-based Armstrong Oil and Gas, in partnership with Repsol, have made major discoveries.

Earlier this year Armstrong sold its 51% share of Pikka, one of its discoveries, to Oil Search, which is now project operator.

Pikka’s resources are estimated at 750 million barrels and Oil Search hopes to expand these to over 1 billion barrels after further drilling.

Willow, a major new discovery by ConocoPhillips, is now estimated to hold 400 to 700 million barrels. The company hopes to expand that but has also found 100 million barrels in a separate find, Narwhal, on state lands to the east.

“We believe we can now compete with shale oil producers in the continental US,” ConocoPhillips Alaska President Joe Marushack said.

“Coiled tubing” drilling

The Nanushuk, a formation covering an area along the Colville River and extending into the northeast NPR-A, is attracting particular interest.

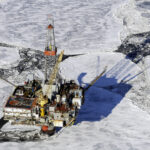

The presence of more oil in these areas has long been known but companies’ confidence they can commercially develop what has been regarded as a marginal resource is now buoyed by rapid advances in horizontal drilling allowing drillers to tap deposits several miles from the surface location of a drill rig.

In “multilateral” wells, as many as five producing legs are drilled off underground from a vertical well to the surface, while in “coiled tubing” drilling, wells can be drilled with flexible tubing at far lower costs than with conventional rotary rigs.

ConocoPhillips has pushed horizontal production wells out to 27,000 feet, over five miles, and when a new specialized rig now being built begins service in 2021, lateral wells out to 40,000 feet, or seven and a half miles, will be possible, ConocoPhillips’ Marushack told a business conference in Anchorage last year.

What this means is that wells drilled horizontally from a single 12-acre gravel pad on the surface will be able to drain oil from 154 square miles of underground reservoir.

Lower capital costs, for barrels of oil developed, has allowed ConocoPhillips to reduce its minimum price threshold for new slope projects from $55 per barrel in 2015 to $42 per barrel now, the company told analysts in presentations last July.

Incremental expansion of existing fields can be done for even less cost, down to $30 per barrel, using technologies like coiled-tubing drilling, the analysts were told.

Some limitations

Independent Hilcorp Energy, another slope producer, is also harnessing a new technology with use of a polymer injection to increase production of thick, viscous oil in the Milne Point field, which is near Prudhoe Bay.

New technologies are also being tweaked. ConocoPhillips, in a new “pentalateral” well (five underground producing legs) in the West Sak viscous oil project has developed methods to access each of the producing legs for work without shutting down the others, company spokesperson Natalie Lowman said.

Some oil service companies have experimented with autonomous drilling units inserted underground to drill on their own, remotely controlled.

Ted Stagg, a retired senior BP drilling engineer in Alaska who helped develop horizontal drilling, said a limitation, for now, to how far wells can be drilled is the cost of recirculating drilling fluid, or “mud”, from the bottom of the hole to the surface.

This is needed to remove rock cuttings and to establish a down-hole pressure with the fluid, to counter any uncontrolled flow of oil or gas – known as a blowout in the industry.