“Geophysics has transitioned from simply finding the resource to defining and understanding it” – MicroSeismic’s Carl Neuhaus

After The Oil & Gas Conference® wrapped up in Denver last week, EnerCom hosted the debut of Oilfield Tech & Innovation Day, where the latest technologies for the E&P industry were the focus.

The day was designed for both VCs and majors who invest in extraction technologies and for companies who have commercialized technologies that are already improving recoveries and are available for operators now. This story is Part 3 of a recap of Oil & Gas 360®’s coverage of Oilfield Tech & Innovation Day.

MicroSeismic

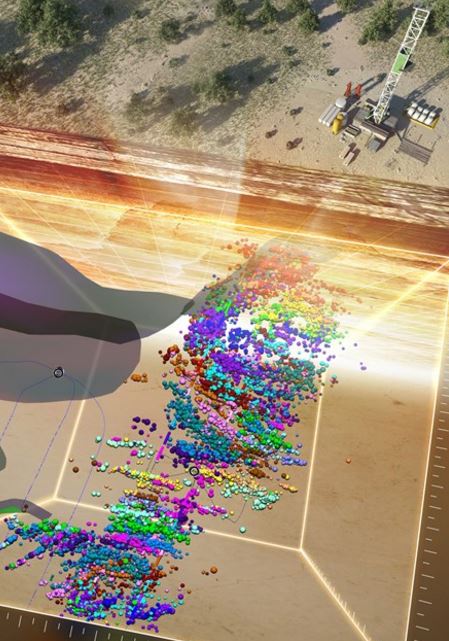

MicroSeismic has built its business around the interactions in the subsurface, with services focused on completions evaluation, hydraulic fracture monitoring and mapping, reservoir monitoring, and seismicity monitoring.

Microseismic wants to show its customers the underground dynamics of their operations. Outside of its services, MicroSeismic has developed technologies and programs, such as its FracStar® and BurriedArray® systems, for underground monitoring.

During its presentation, the company spoke about how geophysics has transitioned from simply finding the resource to defining and understanding it. The science is no longer just involved in locating structural and stratographic traps but instead—with the dawn of unconventional resources—has been geared more and more towards defining locations that will be most economical to produce out of.

In this way, MicroSeismic explained, it was using its technology to better understand how the rock is reacting to treatment. The company uses its acoustic monitoring to detect seismic events—the sound of rock breaking—in the reservoir while a completion is ongoing. The company uses these acoustic signals, collected by its geophones, to listen to the rock as fracturing activities are undertaken and to characterize the quality and efficiency of the fracturing process in real time.

MicroSeismic believes that this technology will have applications in monitoring and optimizing completions, not just in real time, as completions are being undertaken, but afterwards in designing new completions approaches.

The company’s technologies are built to allow operators to map fracture networks, monitor and record frac-stages and fracture interference, and to better understand the stimulated reservoir volume (SRV) that the company is creating.

View the MicroSeismic presentation webcast here.

Stage Completions

Stage Completions presented its technology at the debut of EnerCom’s Oilfield Tech & Innovation Day.

Stage Completions has built new technologies to modernize fracturing techniques. Stage’s goal in building new fracturing tools is to decrease the amount of time, money, and effort put into completions activities.

During its Tech Day presentation, Stage spoke about its Bowhead fracturing system. The Bowhead technology is built to utilize the benefits of sliding sleeve technology and plug-and-perf technology. According to Stage, the Bowhead system can work continuously, be deployed under pressure, stimulate more intervals per day, and be used on single or multi-well pads—mirroring the benefits associated with sliding sleeve technology.

Like plug-and-perf technology, the Bowhead can stimulate the full inner diameter of the well, have unlimited numbers of stages, can be cemented in place or left to an open-hole environment, and is not constrained by pump rate limitations.

Stage believes that its new technology will allow operators to raise EUR, stimulate longer laterals, stimulate in tighter spacing, put more proppant into the formation, conserve fluid, and reduce horsepower.

The company also spoke about working in tandem with Cold Bore Technology’s acoustic monitoring service to monitor the performance of the Bowhead system.

View the Stage Completions presentation webcast here.

Fracture ID

Based out of Denver, Fracture ID has launched its new technology—Drillbit Geomechanics. This technology records and analyses bit vibration during the drilling process. It has a growing client base which includes companies like Devon Energy, Encana Corporation, Hess Corp, and Continental Resources.

During its presentation, FractureID gave information about how its Drillbit Geomechanics technology allowed operators to collect information about in-situ rock properties while the operator undergoes drilling. The ability to learn about rock properties in real-time, during drilling allows operators to quickly build an understanding of the reservoir and the lithologies present.

Drillbit Geomechanics can help an operator identify fractures and thin layers—information which can ultimately be applied to optimizing completions and improving the company’s development strategy.

FractureID spoke about the decrease in rig-time, as other technologies need to be run in-hole following drilling, and a reduction in wireline and LWD costs.

View the FractureID presentation webcast here.

BetaZi

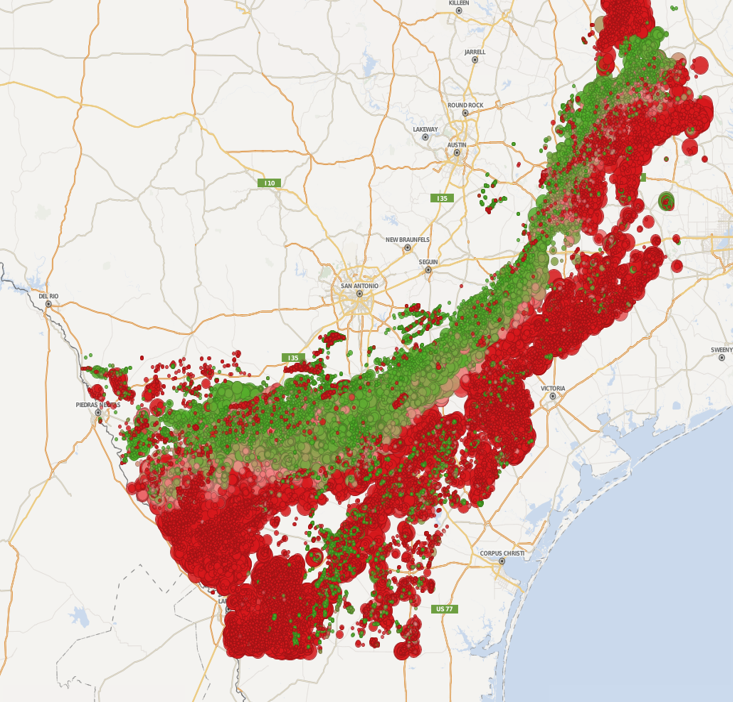

BetaZi creates production forecasting solutions for the oil and gas industry using physics-based predictive analytics, in place of curve-matching that is typically used to create production forecasts.

BetaZi’s product is primarily directed towards producers and financiers. The company itself has modeled over 400,000 wells, and its product has been built to give results quickly and accurately. The forecasting technology was designed with the intent of allowing BetaZi’s clients to quickly make reasonable decisions regarding their assets.

BetaZi’s Basin Studies product has pre-computed, pre-packaged information on major producing basins, with a library of probabilistic well forecasts for all wells with reported and recorded data. The product itself can show the production data itself, type curves and P-Scores—which indicate the reliability of the predicted curves.

During the company’s presentation on EnerCom’s Oilfield Tech & Innovation Day, BetaZi spoke about its predictive analytics product. The company utilizes known information about the physics and fluid flow within established reservoirs to build predictive production curves using statistical analysis.

The product generates decline curves across a range of uncertainty, and validates the fit of those curves with statistical metrics. In this way, the company can give an operating company the correct tools to allow petroleum engineers to make decisions based on quantifiable and reliable information.

View the BetaZi presentation webcast here.

Hi-Crush Partners

Hi-Crush presented its technology at the debut of EnerCom’s Oilfield Tech & Innovation Day at the Denver Downtown Westin hotel on Aug. 17, 2017.

Beyond simply operating sand mines and providing proppant to operators, Hi-Crush has acted as a logistics firm for the oil and gas industry. The company provides services for the transport, storage, and delivery of sand into the wellbore, from the mine all the way up to the well-site.

Hi-Crush has five plants and recently opened a new mine in the Permian basin in July, 2017—allowing it to bring its product closer to the most active basin in the United States. The company spoke about its logistics management service, wherein it provides solutions to sand delivery—offering proppant sand sold at the mine, wellsite, terminal, or delivered via truck or rail.

During its presentation, Hi-Crush spoke about its PropStream™ service, which will handle all logistics from the mine to the well-site. The company has built and delivers sand in its own container system, allowing companies to better design their well-pad layouts for optimal operating efficiency and freeing their staff to deal with other matters outside of the logistics of sand delivery.

The PropStream™ service also utilizes delivery systems that move sand from the containers into the operator’s proppant blender, without the typical sand-dust and sand-loss associated with other delivery systems.

View the Hi-Crush presentation webcast here.