Colorado School of Mines Experts Discuss Improving Fracs, Results

Dr. Will Fleckenstein, Adjunct Professor of Petroleum Engineering at the Colorado School of Mines, Dr. Jennifer Miskimins, Associate Professor of Petroleum Engineering at CSM, and Mike Vincent of Fracwell LLC presented at EnerCom’s The Oil & Gas Conference® 21 on Thursday morning. The panel discussed emerging environmental technologies, hydraulic fracs, and reservoir restimulation techniques in the shale industry.

Dr. Fleckenstein: “The Next Stage of Shale Environmental Developments”

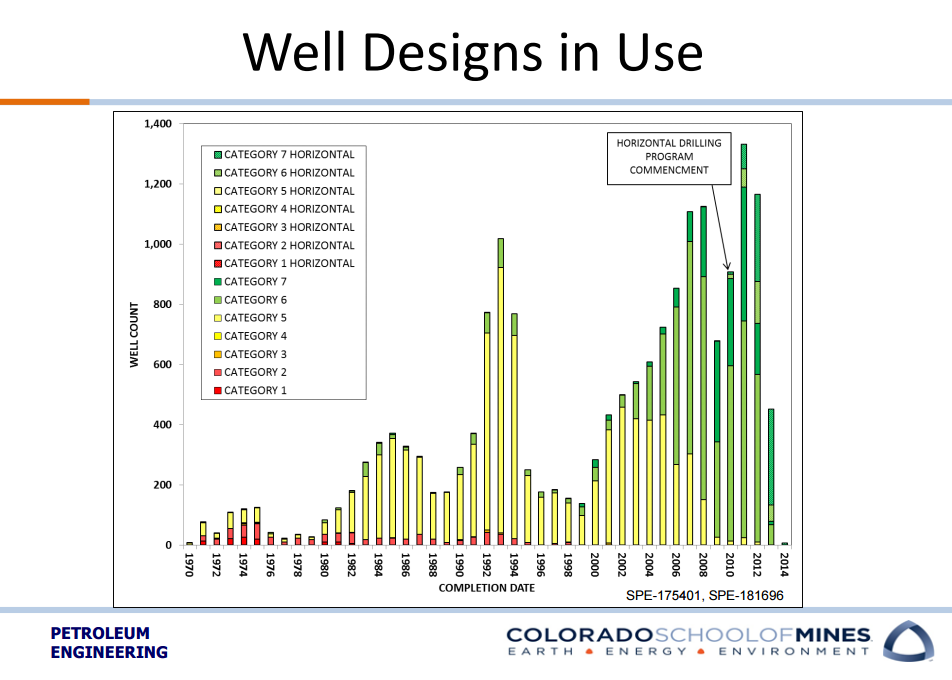

Dr. Fleckenstein’s presentation highlighted a “Big Data” study carried out in the Wattenberg Field near Denver examining failures of different well designs since the 1970s. “We found that the older, less rigorously constructed wells were the ones showing barrier failure and while the newer and more advanced well construction types did not see much failure,” said Fleckenstein.

The study showed that better designed wells (shown in green) have been the norm throughout the shale boom. Wells types that possibly experienced barrier failures (in red) were mainly older, less rigorously designed and were much more common before 1994.

Dr. Fleckenstein said that water is the preferred frac fluid to work with, but that other environmental research projects are seeking to develop less toxic chemicals and water-free fracturing fluids as well as methods to prevent, detect, and react to methane emissions and induced seismicity, and better approaches to land use such as Ultra-Extended Reach laterals, downhole tractors to push drill bits further, multi-laterals, and well pads.

Dr. Miskimins: “We Can Fix your Fracture. We Can’t Fix your Reservoir”

Dr. Miskimins started her presentation by quoting Plato and Thomas Paine, reminding the audience “Necessity…is the mother of invention” and “a long habit of not thinking a thing wrong gives it the appearance of being right.”

She went on to list innovative technologies such as horizontal drilling and multilateral wells that emerged from previous down cycles. The current downturn has continued this trend by spurring numerous technological advances that will increase efficiencies, Dr. Miskimins said.

Miskimins said as an industry we’re still very inefficient in our fracs, and it’s no secret that making completions more efficient is a topic of ongoing interest. Miskimins pointed out that many fracing stages in recent wells have gone untreated, with some reports indicating that only one half of total wellbore distance is producing at a given point, with flows turning on and off. She pointed to fiber optic tools that can collect data on temperature, acoustic, chemical, pressure, and strain to identify inefficiencies, giving operators new avenues to improve fracs.

The characteristics of reservoirs themselves are still a mystery, Miskimins said, and more efficient, “engineered completions” will require better geophysical and geological data. Tracing techniques can improve understanding of which stages and fracs in a well are producing and flowback tracers offer a look at reservoir space between wells.

Other projects mentioned by Dr. Miskimins include replacing water in fracking with CO2 and N2, improvements to artificial lift methods, and better management of pressure in reservoirs.

Mike Vincent: “Restimulation”

Mr. Vincent concluded the panel by examining current issues with underperforming refracturing projects and emphasizing the benefits to the industry as a whole that greater collaboration on the practice would bring.

Vincent pointed out that although the refracturing process has around since the early 1950s, many pilot projects are not well-planned or implemented. “There is also little collaboration or data sharing between companies, which prevents the industry from learning from the past,” he said.

“If operators can start incorporating these learnings in their new wells, we can get some unambiguous answers on whether the underperformance of an individual refrac is a reservoir problem or a fracture problem,” said Vincent.

He talked about “relaxer fracs” as having good results, defining this as pumping one frac, then shutting it off, waiting about 15 minutes and pumping it again.

Vincent said that Russia, Australia, South America, Mexico, Canada and the U.S. are all candidates for widespread restimulation.