Improving Safety at Well Sites

At this week’s Independent Petroleum Association of America (IPAA) meeting, Integrated Environmental Technologies (ticker: IEVM) gave a presentation about its Excelyte™ biocide, which the company says can be used to virtually eliminate hydrogen sulfide (H2S) and bacteria from the oil and gas wells where it is used.

Saving Producers $350-$800 per Well per Month

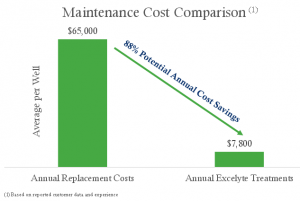

IET estimates that its product offers an 88% annual savings in maintenance costs by eliminating corrosive H2S in the oil and gas being produced. By

taking hydrogen sulfide out of the oil being produced, IET’s product is able to save producers between $350 and $800 monthly per well, just in maintenance costs, according to the company’s presentation.

From 4,000 ppm to 0 ppm

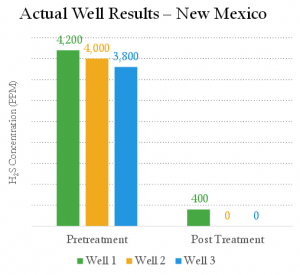

In the first three wells the company tested, H2S levels fell from 4,200 parts per million (ppm), 4,000 ppm and 3,800 ppm to 400 ppm in the first well, and 0 ppm in the second and third wells. The company says that it uses a depot method to deliver its biocide, setting up production near wells in order to reduce shipping costs and meet the customer’s needs. Delivery of the product is made by truck and takes approximately 25 minutes per well, according to the company.

When asked about the cost of the depots, David LaVance, IET’s president and CEO said that they can range in cost from $150,000 to $200,000, and usually pay for themselves within 3 to 4 months.

LaVance said the company had evidence that by lowering the sulfur content of their customers’ oil, customers are able to sell their crude at a higher price. “Our product arguably sweetens [our customers’] product.”

Oil and gas is the largest portion of the company’s business, though the IET products have application in healthcare and food production. The company raised $2 million in February in an equity raise targeting expansion of its oil and gas operations. The company’s biocide is environmentally safe and is certified by the NSF, USDA and EPA. The equipment and solution used by IET are both proprietary.

IET currently has operations in the Uinta Basin in Utah and the Permian Basin in New Mexico, and it is targeting other high-sulfur basins, including the Eagle Ford, Bakken and Monterey Shale. During the company’s presentation, LaVance said that the company’s product has now been used to treat over 150 wells to reduce the amount of H2S and sulfite-producing bacteria in each.

See EnerCom’s Oil & Gas 360®’s exclusive interview with David LaVance here.

Important disclosures: The information provided herein is believed to be reliable; however, EnerCom, Inc. makes no representation or warranty as to its completeness or accuracy. EnerCom’s conclusions are based upon information gathered from sources deemed to be reliable. This note is not intended as an offer or solicitation for the purchase or sale of any security or financial instrument of any company mentioned in this note. This note was prepared for general circulation and does not provide investment recommendations specific to individual investors. All readers of the note must make their own investment decisions based upon their specific investment objectives and financial situation utilizing their own financial advisors as they deem necessary. Investors should consider a company’s entire financial and operational structure in making any investment decisions. Past performance of any company discussed in this note should not be taken as an indication or guarantee of future results. EnerCom is a multi-disciplined management consulting services firm that regularly intends to seek business, or currently may be undertaking business, with companies covered on Oil & Gas 360®, and thereby seeks to receive compensation from these companies for its services. In addition, EnerCom, or its principals or employees, may have an economic interest in any of these companies. As a result, readers of EnerCom’s Oil & Gas 360® should be aware that the firm may have a conflict of interest that could affect the objectivity of this note. The company or companies covered in this note did not review the note prior to publication. EnerCom, or its principals or employees, may have an economic interest in any of the companies covered in this report or on Oil & Gas 360®. As a result, readers of EnerCom’s reports or Oil & Gas 360® should be aware that the firm may have a conflict of interest that could affect the objectivity of this report.